How to Select Your Best Entries for the Graphics Excellence Awards Competition

For more than 30 years, winning in GLGA’s Graphics Excellence Awards competition has been the benchmark for printing excellence in Illinois, Indiana and Wisconsin. Winning generates instant industry recognition, and lets existing and potential clients know they are dealing with the best of the best. Being an award-winning printer or finisher gives your company fresh marketing content, leverage in recruiting new employees, and a morale boost for your current employees.

For more than 30 years, winning in GLGA’s Graphics Excellence Awards competition has been the benchmark for printing excellence in Illinois, Indiana and Wisconsin. Winning generates instant industry recognition, and lets existing and potential clients know they are dealing with the best of the best. Being an award-winning printer or finisher gives your company fresh marketing content, leverage in recruiting new employees, and a morale boost for your current employees.

Careful consideration and microscopic attention to detail are critical when selecting your entries.

Former judge (and Indiana native) Glenn Petry was in the industry as a printer, print buyer, and printing consultant for more than 65 years. He was recognized nationally as a judge for various Printing Industries of America affiliate print competitions, judging more than 150 different shows over 20 years in the United States. He judged the GEAs numerous times.

Former judge (and Indiana native) Glenn Petry was in the industry as a printer, print buyer, and printing consultant for more than 65 years. He was recognized nationally as a judge for various Printing Industries of America affiliate print competitions, judging more than 150 different shows over 20 years in the United States. He judged the GEAs numerous times.

Glenn developed a list of guidelines and tips for selecting entry-worthy pieces that will help your company take home high honors. His primary mandate: “Don’t wait until the last minute to select your entries.” Once your company makes a commitment to enter, involve your entire team in the process. Have experienced and knowledgeable personnel select two perfect samples of each potential entry as it is produced. Store those pieces in a safe location until it’s time to make your final entry selections.

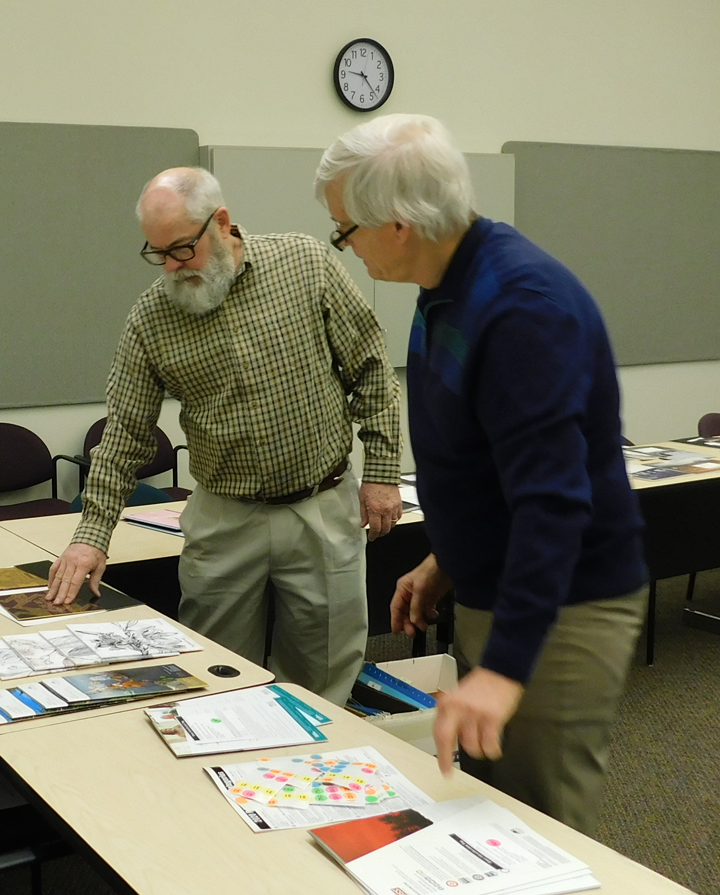

Our judges hard at work evaluating entries.

Before judging begins, all of the entries are grouped by category and displayed on tables. The team of expert judges evaluates each piece on its own merits as well as in comparison against the other entries in its category to determine what award level it earns. An entry is judged first on technical expertise and the quality of printing, then on design features and overall graphic appeal. Any entry with visible technical flaws will be disqualified from the judging – so please check your samples carefully!

How to Select Qualified Entries:

Glenn Petry’s Technical Properties Guide

- No Hickeys

- No Roller or Gear Marks

- No Scratches or Smudges

- Stitching/Binding/Finishing – must be consistent without cracking on spine or scores

- Registration – no color overlaps

- Line Drawings/Halftones – clear with no flooding

- Ink Lay – smooth and complete

- Color Consistency

- Photo Consistency

- Crossovers – must be in alignment

- Folios – must be positioned consistently

- Creep Control

- Use of Paper – must elevate the piece

- Smoothness – no excessive use of spray powder

- Embossing – clean and sharp

- Die Cuts – clean with no heavy nicks

- Gates – must be in alignment

- Paper Grain Direction – no cracking of backbone

- Foil Stamping – registration and proper pressures

- Coatings – appropriate usage and consistency

Glenn liked to say that he was looking for a entry that presented “multiple ways to fail” – meaning a piece with several properties, processes or techniques. These pieces and their unique challenges are what bring out the best in our GEAs competitors.

GEAs Categories, Call for Entries and Online Entry page

The Beginner’s Guide to the GEAs

The team from Walsworth, Ripon, WI, celebrates their wins at the 2025 Awards Celebration.